The foul-smelling fuel that could power big ships

- Published

Marine engines like this one are being readied to run on ammonia

An enormous engine, the height of three floors, growls loudly at a test centre in Copenhagen. Nearby a team of engineers supervise it from a control room resembling a ship's bridge.

Usually such an engine would be propelling a large ship across the sea, but this one is being prepared to take part in a ground-breaking project.

Engineers want to see if they can make it run on liquid ammonia.

Ammonia has long been a key component in fertiliser, cleaning products and refrigerators.

But in the search for new cleaner fuels, the foul-smelling substance has emerged as a frontrunner to power ocean-going ships.

The test engine had to be shipped into Copenhagen

Around 90% of all goods traded globally are transported by sea. But ships are gas guzzlers. Marine transport produces around 2% of global greenhouse gas emissions.

The International Maritime Organization (IMO) wants to halve emissions by 2050, from 2008 levels. That requires a substantial shift to green technology.

Brian Soerensen, a research and development chief at Man Energy Solutions, says several fuels are being explored: "One of the options we believe will be ammonia. Methanol could be another one, biofuel could be a third."

Ammonia has an advantage as it contains no carbon, so can burn in an engine without emitting carbon dioxide.

By early 2024, Man Energy Solutions plans to install an ammonia-ready engine on a ship. The first models will be dual-fuel, able to run on traditional marine gas oil as well.

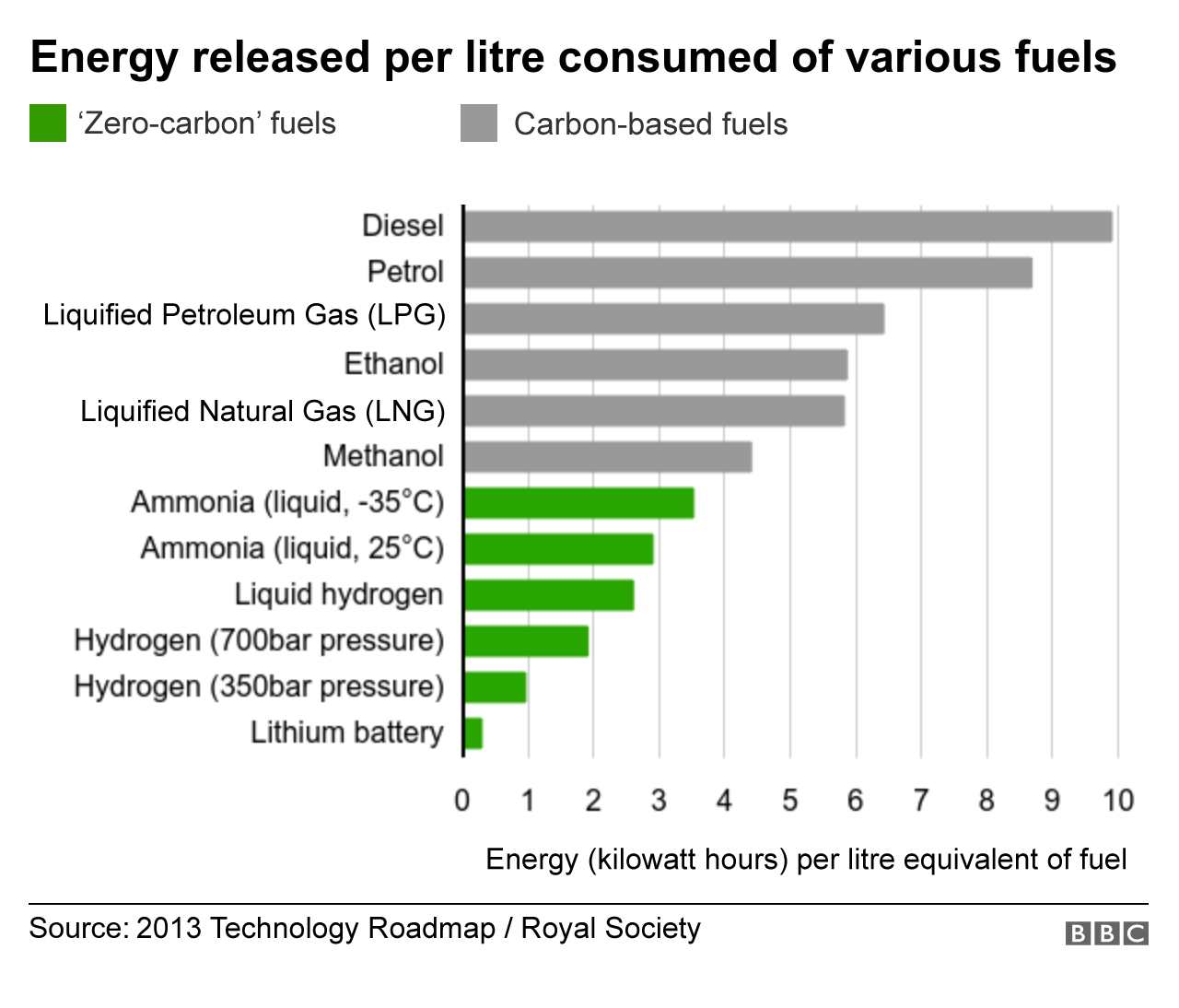

While it is less energy-rich than today's marine fuels, liquid ammonia is more energy-dense than hydrogen, another zero-emission fuel.

Hydrogen has already powered cars, planes and trains. It's cheaper to produce than ammonia, but harder to handle as it has to be stored at minus 253C. Ammonia becomes liquid below minus 34C and at higher temperatures if under pressure.

"Ammonia sits very nicely in the middle," says Dr Tristan Smith, an expert in low carbon shipping from University College London. "It's not too expensive to store and not too expensive to produce."

There are challenges. Burning ammonia can create polluting nitrous oxides, therefore the exhaust needs cleaning up. It is also toxic, so requires careful handling and storage.

However, safety know-how and some port infrastructure are already in place, says Mr Soerensen, because the fertiliser industry is well-established.

"It's being transported seaborne today. We know how to handle ammonia on board a ship, not as a fuel, but as a cargo."

Viking Energy will be engineered to run on ammonia and liquefied natural gas

Meanwhile, Norwegian shipping company Eidesvik plans to install ammonia fuel cells on a vessel by late 2023. Like batteries, these generate electrical energy to power a motor. Project partner Prototech has already begun developing a test version.

The supply ship, Viking Energy, will sail round-trips of 345 miles (555km). The hybrid vessel will also use liquefied natural gas (LNG).

Vermund Hjelland, vice president of technology and development at Eidesvik, says fuel cells are more efficient and cost-effective, for such short, predictable routes. "You can have smaller tanks and get more kilowatt-hours out of the same amount of fuel.

"The picture is different compared to a super-tanker," he adds. "It very much depends whether weight is an issue."

Around $55bn (£42bn) of ammonia is manufactured annually, mostly for fertiliser. But the industry has a heavy environmental footprint, accounting for 1.8% of global CO2 emissions. Fertilisers can also harm water and air quality.

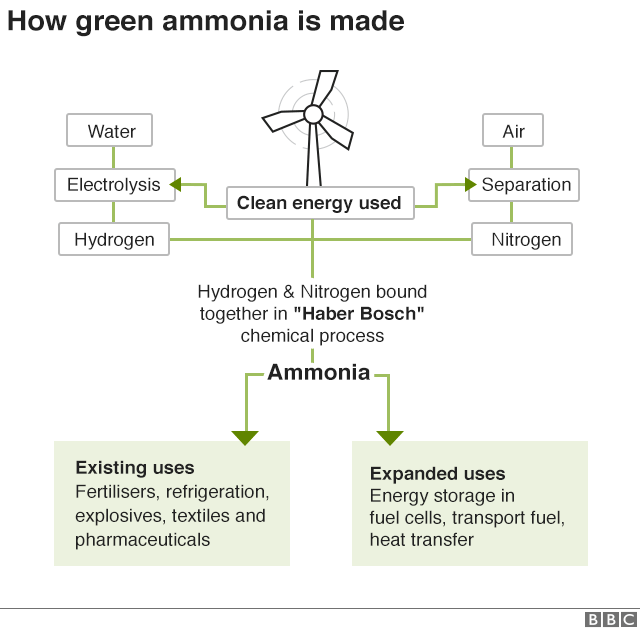

Manufacturing ammonia requires nitrogen and hydrogen gases. Often this hydrogen is extracted from natural gas (methane). The process releases carbon and needs lots of power.

New, cleaner ways to make ammonia are emerging. One method, blue ammonia, involves capturing and storing the carbon. More promising, green ammonia, eliminates the use of fossil fuels altogether.

This test plant in Denmark is developing a more environmentally friendly way to make ammonia

In the heart of rural Jutland, western Denmark, research is under way at a brand new pilot plant in Foulum.

Haldor Topsoe, which makes catalysts used in the production of ammonia, together with scientists from Aarhus University, is aiming to make ammonia from water, air and renewable electricity.

"Those three feedstocks you can find in many places around the world," says Pat Han, Haldor Topsoe's director of research.

"Instead of utilising fossil energy... we simply take wind and solar energy, and within minutes, we have a liquid fuel at the other end," says Mr Han.

Inside a transparent box, the size of a shipping container, sits a maze of pressure gauges and insulated silver pipes.

"We use electricity to electrolyse water and generate hydrogen. And then we're using air to add nitrogen to the system," explains Behzad Partoon, a postdoctoral researcher from Aarhus University. Later these gases will be combined to make ammonia.

New technology called a solid oxide electrolysis cell (SOEC) streamlines these steps, by combining the nitrogen purification system with the hydrogen production process,

"We're going to save more energy and reduce the energy intensity of ammonia production," says Mr Partoon. "It makes the whole process much cheaper."

Now they're testing the technology's stability over longer periods of time and making adjustments, before scaling up to industrial quantities of production.

Currently power comes from the grid. "It's not far from reality with real green energy," says Anne Mette Frey, an associate professor at Aarhus University. "Everything is set up."

Ammonia can be made from water, air and renewable electricity

Green ammonia is being developed elsewhere, including in Australia and Chile.

There are other potential uses including cleaner fertiliser production and the storage of surplus wind and solar energy.

Haldor Topsoe expects green ammonia to be commercially available as early as 2022 or 2023.

But marine transport may face other hurdles. A Global Maritime Forum report, suggests that meeting the IMO's 2050 goal, by shifting primarily to green ammonia fuel, would need more than a $1 trillion of investment.

Dr Tristan Smith, one of the report authors, says that is achievable. As renewable electricity and technology costs come down, green ammonia will become more competitively priced, he says. "By the late-2020s, maybe mid-2030s, we will have some relatively low prices. But that could still be more expensive than oil."

Man Energy Solutions' Brian Soerensen believes governments will have to help drive the transition. "A certain amount of emission tax will have to be in place."