Bloodhound Diary: Precision and accuracy

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will mount an assault on the world land speed record. Bloodhound will be run on Hakskeen Pan in Northern Cape, South Africa, in 2015 and 2016.

Wing Commander Andy Green, the current world land-speed record holder, is writing a diary for BBC News about his experiences working on the Bloodhound project and the team's efforts to inspire national interest in science and engineering.

It was just over three years ago that Rolex became Bloodhound's official timing partner.

Their support has been invaluable in helping us to build the world's first 1,000mph car.

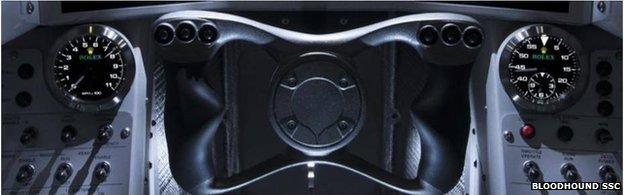

Rolex has also designed and made two key instruments for Bloodhound's cockpit, and this month we unveiled them in public, external for the first time.

When we first talked to Rolex, they were intrigued by our requirements for a precise and fail-safe cockpit speedometer, together with a chronometer/stop-watch.

After three years of work, they have produced the most accurate and reliable instruments ever to be fitted into a land speed record car.

Precision and accuracy at 1,000mph

The speedo is an essential back-up for Bloodhound, to make sure that I can stop the car safely at any stage.

If the main speed readout fails, I need to know exactly how fast the car is going, so that I can put the airbrakes and/or drag chutes out at the correct speed.

Deploy the chutes too fast and they will simply tear off, leaving Bloodhound SSC to run off the end of the track. Deploy the chutes too late, and there will not be enough desert left to stop, and once again the car will run of the end.

With previous record cars, this has not really been a problem.

The chute speed limit is nearly 700mph, so they could be deployed at almost any stage, as even Thrust SSC was only above 700 for a few seconds.

The car gets longer

However, Bloodhound's top speed of 1,000mph makes slowing down a more challenging problem, and the chute deployment speed is critical. Hence the need for the Rolex speedometer.

The speedo has its own GPS sensor, driven by an internal battery, to provide a precise and reliable speed readout. Why use an analogue dial, rather than a digital readout? Simple - because it's the easiest type of display to read.

Jet fighters have analogue back-up instruments for exactly that reason.

The Rolex chronometer has a wider range of uses. The FIA World Land Speed Record, external requires two passes through the measured mile, in opposite directions, within one hour.

I'm not going to be timing the hour precisely from the cockpit, as that's the timekeepers' job (I'll be plenty busy enough at 1,000mph without trying to hit the stopwatch as we enter the timing lights!).

However, keeping track of the time during our record attempts will be useful, as we get ready for the return record run.

I'll also be timing various systems on the car. For instance, after a high-speed run the jet engine needs between two and five minutes at idle, to let it cool before I shut it down.

I'm betting that two minutes should be enough, while Rolls-Royce has been more cautious and advised five minutes. Like so many other details, this is something we'll test once we start running, to find out exactly how quickly the engine cools down.

Luke fits the 1,000mph steering rack to the "Goat's Head"

If the Rolls-Royce team is reading this, then I promise we'll stick to your figures to start with!

Just like the speedometer, the chronometer is analogue, to make it easy to read. The clock also takes its time signal from the GPS that drives the speedo, so it should be correct to about one millionth of a second. That's accurate.

The build of the car's structure presses on. For the first time in many months, the car got substantially longer this month, with the first sitting of the front suspension sub-assembly, external. Nick-named "the goat's head", its four main components started life as 924kg of aluminium, provided by Thyssen-Krup.

Forged (heated and pressed under thousands of tonnes of pressure) four times for incredible strength, the material underwent 103 days of machining by AMRC in Sheffield.

You can see a video of the machining process in this AMRC video clip, external. The final precision-made components weigh just 68kg and will support the huge loads (20+ tonnes) of Bloodhound's front suspension, while all the discarded metal is captured for recycling.

Part of our four-tonne hinge set

These four main parts will be joined by 268 other bespoke components that make the main assembly, on to which we'll bolt the outboard wishbones, uprights and so on. Almost all of those parts are in hand and the first mock-up assembly will start soon.

Manufacture of the fin parts is also going well, with all 31 of the small components now completed. The whole process will eventually turn three tonnes of aluminium into a total of 75kg machined structures, plus a lot more "swarf" for the recycling bin.

The skins will add another 30kg to the fin, to produce a structure over two metres tall. It's already home to 20,000 names, so if you haven't added yours yet, click here to book your place, external for a 1,000mph ride.

Bloodhound's unique airbrake system, external is now coming together quickly. This month we will have all the mechanical parts (less the doors themselves) to assemble the entire airbrake system for the first time on the car.

Captain Slow's contributions

The airbrake doors will produce a total drag load of around five tonnes, all supported by the hinges, so they need to be strong. That includes two small components machined by Top Gear's James May on his home lathe (not something most TV celebrities have, I'm guessing).

These are now with the team for rigorous quality checking. Captain Slow working on the world's fastest car… welcome to the extraordinary world of Bloodhound!

The hinge components will support the airbrake doors as they deploy at supersonic speeds, slowing Bloodhound down from 1,000mph in just over five miles.

In most sports, five miles sounds like a long way. However, when you're doing a mile in 3.6 seconds, it doesn't seem quite so far. Coming out of the measured mile at 1000+ mph, the airbrakes are going to be my best friends.

With the arrival of the airbrake parts, we now have all the components for the upper-rear chassis.

Viv fits the airbrake system

The assembly team has everything they need to drill off and "skin pin" the structure (skin pins are small screw-in metal pins that hold the structure together, while all the rivet holes are drilled and counter-sunk).

Once all the drilling is completed, we can then break down the assembly to anodise and prime the parts.

We will then bond and rivet the whole structure, which is going to be a busy job. After we start to apply the bonding agent (Redux glue film), we've got 30 days to complete the assembly and get the whole structure into the autoclave at the National Composites Centre, to "cook" the glue.

During those 30 days, we've also got to insert 11,500 rivets.

It's going to be quite a race! Once the upper chassis is completed, we can then test-fit the EJ200 jet engine into the car for the first time, and we're already working on the bits to "hang" the engine in the chassis. Won't be long now.

While we're working hard on the car, planning continues in the Northern Cape of South Africa for the arrival of Bloodhound next year. Our Track Boss, Rudi, has just been out to Hakskeen Pan, external to have a look at the desert, after the recent rainy season.

For the first time, he was able to drive from one end to the other at high speed (for a normal car, that is), to look at the whole 12-mile length.

He sent us back this video of the world's best race track, external, which is nearly finished.

As Rudi succinctly put it: "It's a relatively boring video, but I think that boring is what we are after." Can't wait to drive down it at some proper high speeds, at which point things will become just a little bit more exciting.

- Published28 April 2014

- Published28 January 2014

- Published25 December 2013

- Published19 December 2013

- Published4 July 2013

- Published13 May 2013

- Published3 October 2012

- Published7 February 2011

- Published5 March 2011

- Published13 November 2010