Flat lens promises possible revolution in optics

- Published

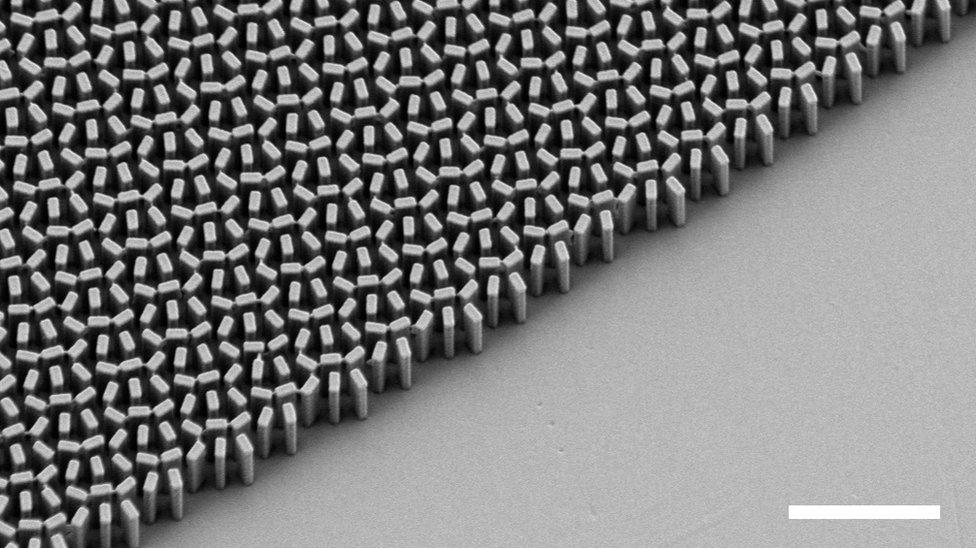

This electron microscope image shows the structure of the lens (white line is 0.002mm long)

A flat lens made of paint whitener on a sliver of glass could revolutionise optics, according to its US inventors.

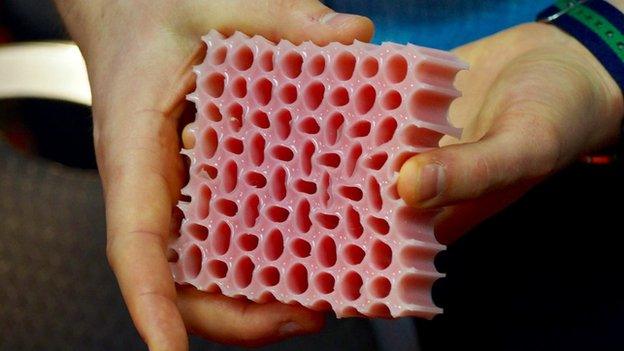

Just 2mm across and far thinner than a human hair, the tiny device can magnify nanoscale objects and gives a sharper focus than top-end microscope lenses.

It is the latest example of the power of metamaterials, whose novel properties emerge from their structure.

Shapes on the surface of this lens are smaller than the wavelength of light involved: a thousandth of a millimetre.

"In my opinion, this technology will be game-changing," said Federico Capasso of Harvard University, the senior author of a report on the new lens which appears in the journal Science, external.

The lens is quite unlike the curved disks of glass familiar from cameras and binoculars. Instead, it is made of a thin layer of transparent quartz coated in millions of tiny pillars, each just tens of nanometres across and hundreds high.

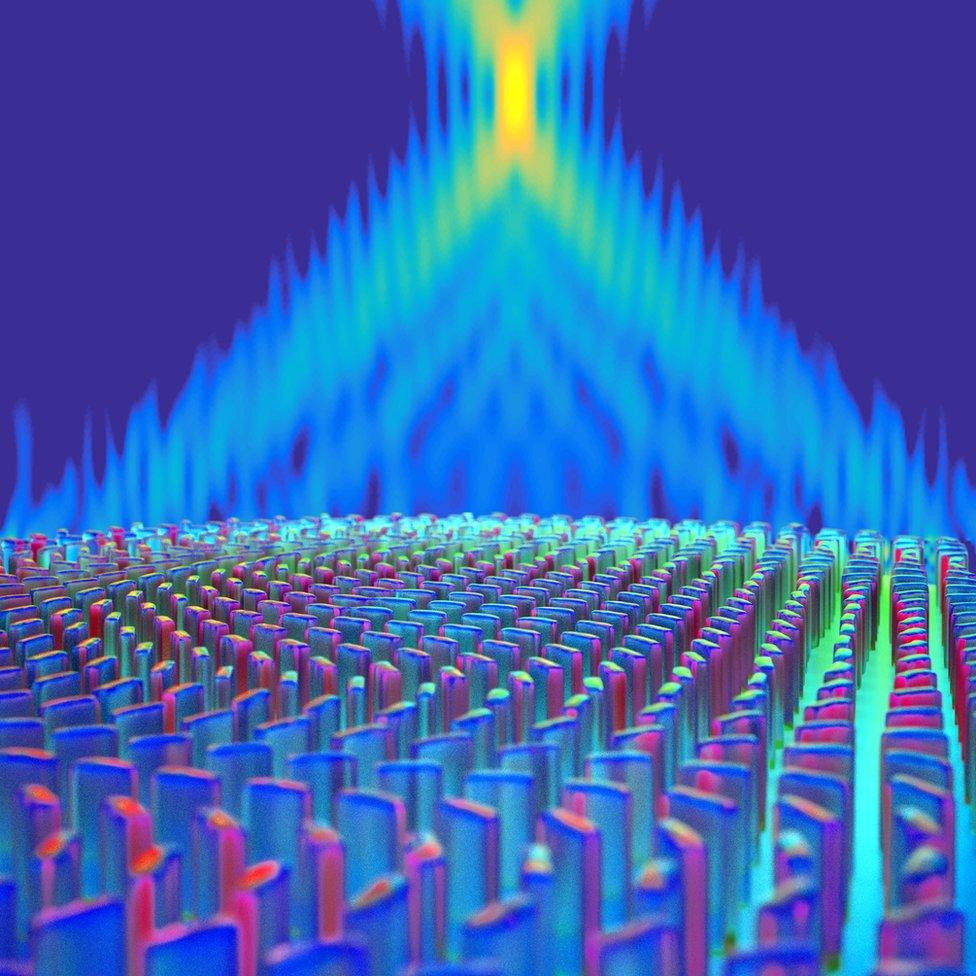

Singly, each pillar interacts strongly with light. Their combined effect is to slice up a light beam and remould it as the rays pass through the array (see video below).

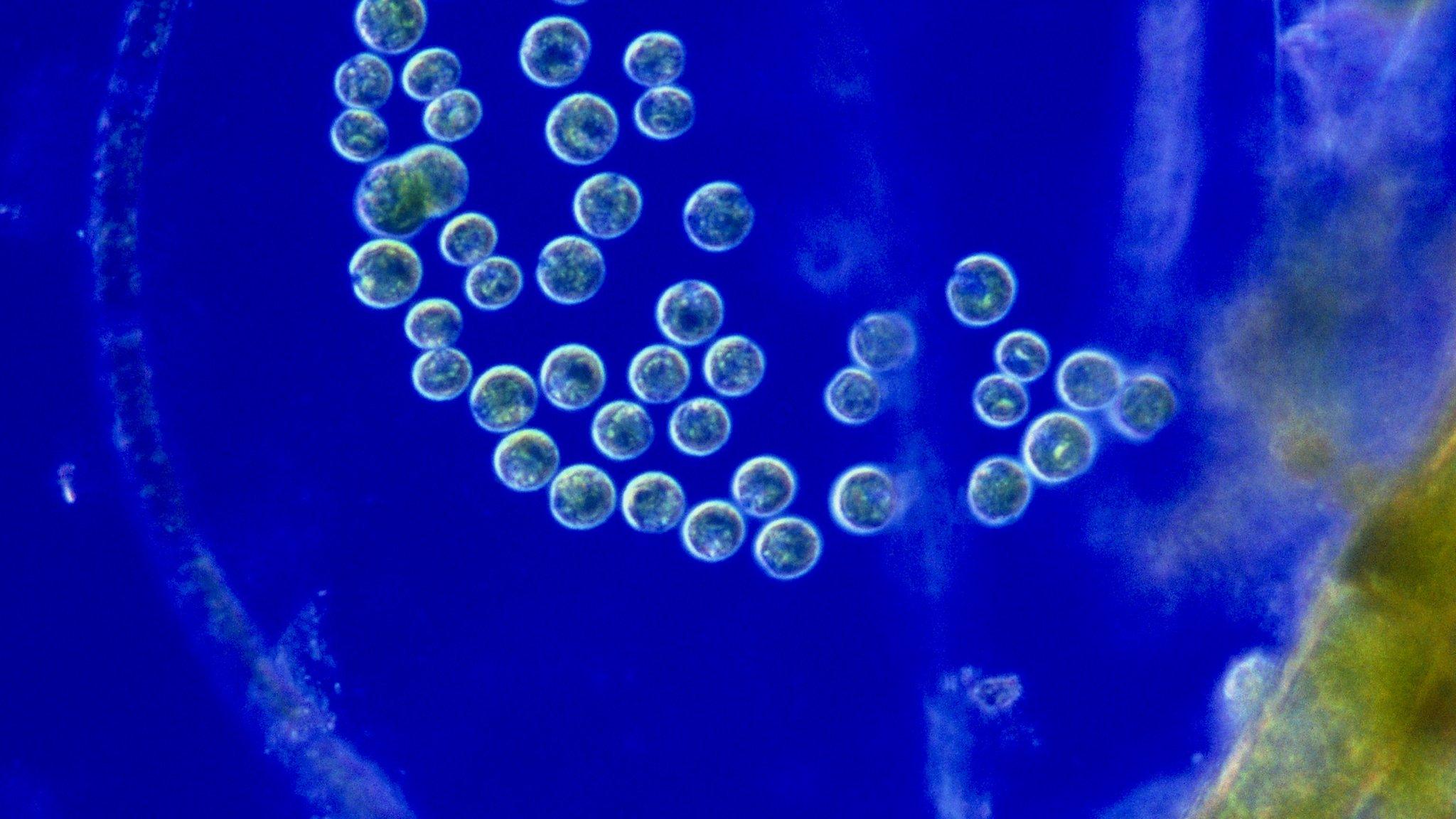

Light passing through the "metalens" is focussed by the array of nanostructures on its surface (video: Capasso Lab/Harvard)

Computer calculations are needed to find the exact pattern which will replicate the focussing effect of a conventional lens.

The advantage, Prof Capasso said, is that these "metalenses" avoid shortfalls - called aberrations - that are inherent in traditional glass optics.

"The quality of our images is actually better than with a state-of-the-art objective lens. I think it is no exaggeration to say that this is potentially revolutionary."

Those comparisons were made against top-end lenses used in research microscopes, designed to achieve absolute maximum magnification. The focal spot of the flat lens was typically 30% sharper than its competition, meaning that in a lab setting, finer details can be revealed.

But the technology could be revolutionary for another reason, Prof Capasso maintains.

"The conventional fabrication of shaped lenses depends on moulding and essentially goes back to 19th Century technology.

"But our lenses, being planar, can be fabricated in the same foundries that make computer chips. So all of a sudden the factories that make integrated circuits can make our lenses."

And with ease. Electronics manufacturers making microprocessors and memory chips routinely craft components far smaller than the pillars in the flat lenses. Yet a memory chip containing billions of components may cost just a few pounds.

The lens is much more compact than a traditional microscope objective

Mass production is the key to managing costs, which is why Prof Capasso sees cell-phone cameras as an obvious target. Most of their other components, including the camera's detector, are already made with chip technology. Extending that to include the lens would be natural, he argues.

There are many other potential uses: mass-produced cameras for quality control in factories, light-weight optics for virtual-reality headsets, even contact lenses. "We can make these on soft materials," Prof Capasso assured the BBC.

The prototypes lenses are 2mm across, but only because of the limitations of the Harvard manufacturing equipment. In principle, the method could scale to any size, Prof Capasso said.

"Once you have the foundry - you want a 12-inch lens? Feel free, you can make a 12-inch lens. There's no limit."

The precise character of the lens depends on the layout and composition of the pillars. Paint-whitener - titanium dioxide - is used to make the pillars, because it is transparent and interacts strongly with visible light. It is also cheap.

The minuscule pillars have a powerful effect on light passing through

The team has previously worked with silicon, which functions well in the infrared. Other materials could be used to make ultraviolet lenses.

Or to get a different focus, engineers could change the size, spacing and orientation of the pillars. It simply means doing the computer calculations and dialling the results into the new design.

The team is already working on beating the performance of its first prototypes. Watch this space, they say - if possible, with a pair of metalenses.

- Published17 January 2013

- Published4 March 2015

- Published4 November 2010

- Published9 February 2016