Bloodhound Diary: A 'Great' message to share

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will first mount an assault on the world land speed record (763mph; 1,228km/h). Bloodhound, external should start running on Hakskeen Pan in Northern Cape, South Africa, in 2017.

I was lucky enough to spend a couple of days in India in November with the "GREAT Britain" Campaign, supporting the India/UK TECH Summit.

It was a very high-powered event, with opening speeches by Prime Minister Modi of India and the UK Prime Minister Theresa May.

Both PMs highlighted the importance of technology and its increasingly vital role in our future.

The next two keynote speakers developed this theme.

Sir James Dyson talked about the need to train more scientists and engineers, which is of course a key part of what Bloodhound is all about.

Next up was Sir Andrew Witty, boss of Glaxo Smith Kline, who talked about a world where it's possible to share huge amounts of data with millions of people all at the same time.

This is exactly what Bloodhound is going to, streaming live video and data to a global audience every time we run the car.

These eminent speakers provided the perfect "warm up" for the next presentation, which was Bloodhound.

As well as talking about Bloodhound's education programme and the most high-technology Land Speed Car ever, I was careful to point out the key links with Indian technology, ranging from the software used to machine the rear suspension assembly to the 3D-printed titanium steering wheel.

The Bloodhound presentation went down very well with the TECH Summit conference in New Delhi, and was even more popular with a school audience in Bangalore the following day.

After talking about the car, we got the whole class to do a design study for the Bloodhound Desert Camp.

The Prime Minister joins Bloodhound Education

What were the five key things that we would need in South Africa next year?

And how would you lay out the camp?

The lesson went brilliantly well with the kids (a wide range of ages) really enjoying it.

If you want to do a similar "Bloodhound lesson" at a local school, then please do get in touch with our education team, external. They would love to hear from you.

The kids in Bangalore came up with some great ideas for the desert camp, just in time to present some of them to Prime Minister Theresa May, who joined the lesson for the last 10 minutes.

I told the PM that we were doing a lesson about a new Land Speed Record Car called Bloodhound. "I know," she said. "I was talking about Bloodhound in my speech last night."

It seems that we can add the UK Prime Minister to the long list of Bloodhound fans.

13 tonnes? No problem

While we were in India talking about the car's technology, work continued at the Bloodhound Technical Centre to make it all happen.

The prep work on various bits of the chassis included NDT (non-destructive testing) of the brake chute bracing structure.

This V-shaped beam takes the loads of the brake chutes, which can be extremely high.

The maximum deployment speed is likely to be around 650mph, giving a steady-state drag load of 90kN (9 tonnes) with a potential "shock" load of up to 13 tonnes during the opening sequence.

With this kind of load going through it, we need to make sure that the brace doesn't have any cracks or faults in the metal.

The brace was sprayed with a penetrating dye to find even the smallest imperfection and - thankfully - it passed with flying colours.

Supersonic plumbing

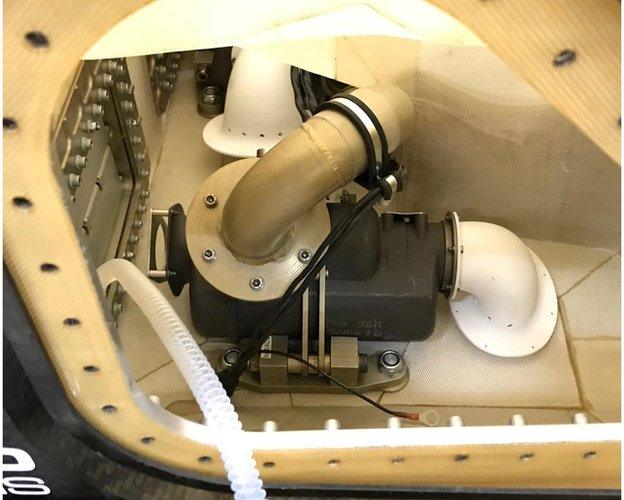

The preparation for December's fuel system test is also nearing completion.

The fuel tanks are now being installed for the final time (assuming all goes well with the testing, of course).

As briefly described last month, there are three separate fuel tanks in the car.

The 500-litre main tank contains more than enough fuel to start up the jet engine, do a full-reheat run to the other end of the desert, and then run the engine at idle for a few minutes to stabilise the temperatures before shutdown.

The 2x100-litre "auxiliary" tanks, tucked in the sides of the chassis behind the main tank, are there just in case we have a few minutes' hold-up before a run, while we're waiting for the "all clear" to start.

It would also allow me to "drive" the car at slow speed back to our desert camp at the end of a run, if required.

No sloshing please

In effect, this extra 200 litres of jet fuel is there to add some flexibility to our start-up and shutdown process.

All three tanks are made by Advanced Fuel Systems and are contained in hugely strong carbon fibre boxes with 15mm thick walls (that's very thick for carbon fibre).

Inside the carbon fibre boxes there are flexible tank liners, which are filled with foam.

This is the same type of foam filling used in race cars, to stop the fuel "sloshing" backwards and forwards, or from side to side, when the car is running.

The main tank is also split into two halves across the car, to reduce the load on the rear wall of the tank.

Jet fuel has a density of about 0.8 (compared with water), so 500 litres of jet fuel weighs around 400kg.

Pumps and baffles

At our peak acceleration of 2G that's 800 kg of load on the rear wall of the main tank.

The car slows down at 3G, so (if the tank is still mostly full) then the load could be up to 1,200kg - about the weight of a small family car.

Splitting the tank shares the load out, with the inner "baffle" taking half of the load.

The baffle has one other vital job to do. Simple flap valves in the baffle allow fuel to flow from the front of the tank to the back half, but not the other way.

The fuel pump for the EJ200 jet engine is near the back of the tank, where the fuel will be thrown under 2G of acceleration.

When the car slows down, all of the remaining fuel will be thrown towards the front of the tank.

In order to keep the jet engine running at idle, it still needs a fuel supply, which is provided by the fuel trapped in the back half of the tank behind the baffle. Simple.

'Who else but me…?'

All of this system is now being bolted together to test the seals, the flow between the tanks, the fuel feed from the pumps, and our ability to refuel and defuel the car.

A small team will be off down to the Bloodhound test site at Newquay Aerohub for a few days in December, to pump fuel in and out until they're happy that it all works. One less thing to worry about when we get to the desert next year.

As I described in last month's diary, external, the desert team in South Africa has done an incredible job of preparing the world's best supersonic racing track for Bloodhound.

While we were out there celebrating their achievement, we made a short video of the whole event, which you can see here, external. I love the bit where Justice Bekebeke, Director General of the Northern Cape Provincial Government, describes how excited they all are that Bloodhound SSC is coming to break the World Record "in our own back yard".

Even better is his description of how the track team see their contribution to this huge event: "…who else can help it, but me?" With pride and determination like that, it's obvious why they've realised this remarkable feat, the largest area of the planet ever hand-cleared for motor racing. Amazing.

We've still got a lot to do to get the car ready to run in South Africa next year, so we're hard at it. In the meantime, you can enjoy the run-up to Christmas with our Bloodhound Advent Calendar, external.

It promises "supersonic prizes" to be won - I don't know what they are, so you'll have to follow the link to win and find out. Good Luck and a very Happy Supersonic Christmas to you.

- Published8 November 2016

- Published13 October 2016

- Published26 September 2016

- Published29 July 2016