Ford's Southampton and Dagenham closures mark end of era

- Published

A convoy on the Queen Elizabeth II Bridge in Essex marks the 40th anniversary of the Ford Transit van in August 2005.

For more than a century, Ford has manufactured vehicles in Britain, at its peak rolling more than 3,000 cars a day off its production lines.

The announcement of the closure of the Transit van factory in Southampton and part of its original factory in Dagenham is a further blow to the country's association with the brand.

Along with the loss of industrial heritage, there will also be the removal of around 1,400 jobs and knock-on effects for the local economies on the south coast and Essex.

In 1976, the one millionth Transit was produced in Southampton.

The engine plant in Dagenham, as well as factories in Halewood, Merseyside and Bridgend, South Wales, will continue to manufacture parts on Ford's behalf maintaining an industrial association with the brand who once claimed how "everything we do, is driven by you".

The Transit factory at Swaythling is the last Ford vehicle assembly plant in the UK.

Around 2.2 million Transits have been made in Southampton since 1972 while the first vehicle, the Model AA truck, rolled off the Dagenham production line in October 1931.

Dagenham will continue to play a part as it develops a next-generation, low-CO2 2.0-litre diesel engine.

The plan is to see it power future Ford vehicles from 2016.

But the US company, based in Dearborn, Michigan, will still employ around 10,000 people across the UK even after the doors close in Southampton next July.

'Excess capacity'

Stephen Odell, Ford's chairman and chief executive in Europe, stressed one in four engines will still be produced in the UK.

He said: "We, like any other manufacturer, have to reflect the economic and business conditions we're involved in.

"We've seen a dramatic decline in the economic situation and indeed the automotive industry as a whole.

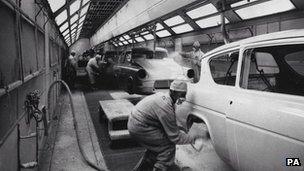

Vehicles roll off the production line at Ford's Dagenham plant in the 1960s

"In terms of vehicle numbers, we're running a fleet around 14 million a year in western Europe, that's 20% below where we were in 2007.

"The double-dip recession has really exposed that and in any business, you simply cannot run with that level of excess capacity over a sustained period of time."

Production of the Transit van slumped from 66,000 in 2008 to 28,000 last year after the Swaythling plant moved to single shift operation and a four-day week.

The workforce has been reduced over the years to just 500. At its height in the late 1970's 4,500 people worked at the plant.

'Not a surprise'

In 2009, half the workforce was offered voluntary redundancy and production was cut.

Professor David Bailey, an automotive industry expert from Coventry University, said: "It's not a surprise, the writing was on the wall when Ford shifted production to Turkey - it's been vulnerable since then.

"It's ironic as the company has been marketing it as the back bone of Britain.

"It is the end of a century, so symbolically its very important.

"What's left of the industry in Britain is very good - but we need to think about how we support the industry."

Once the factory floors empty, the wider impacts will really bite for families of affected staff.

"It's a sad day for everyone involved with the Swaythling plant, and a real loss to the local community," said What Car?'s editor in chief, Chas Hallett.

He added: "But, it's not altogether surprising given that currently it's much more economical to mass produce cars in countries such as Romania and Turkey."

- Published25 October 2012

- Published24 October 2012

- Published24 October 2012

- Published25 September 2012

- Published6 September 2012