Coronavirus: Imperial College team design 'low-cost' ventilator

- Published

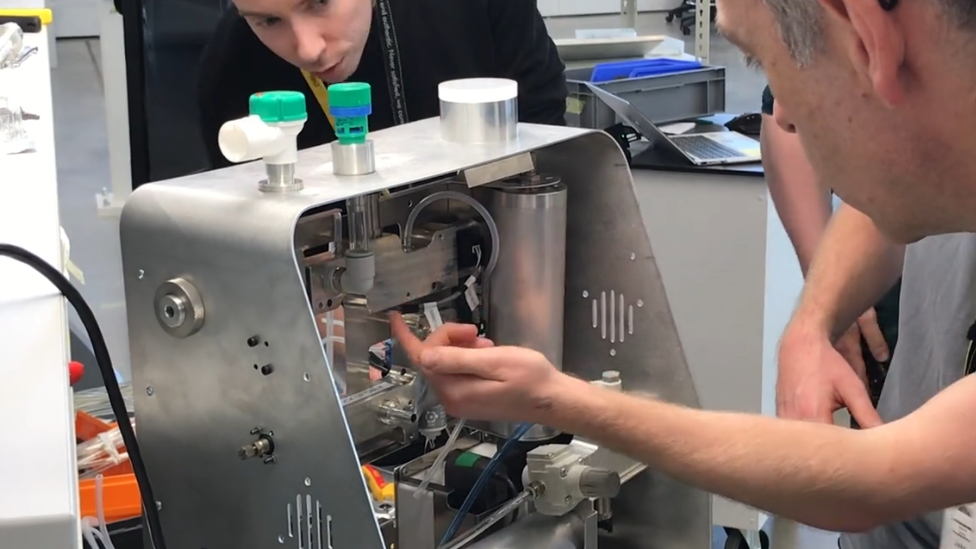

A team of researchers designed the JamVent ventilator in three days

A team of engineers and medical experts have revealed their designs for a "low-cost" ventilator.

The JamVent prototype was built in response to the government's appeal for the devices to tackle coronavirus.

Its creators from Imperial College hope its "simple components" and low costs mean it could be used in developing countries, and have released their drawings online, external for others to use.

However, the prototype still needs to pass clinical trials.

The team in London built the ventilator for about £1,500 following an appeal by the government, which has seen a scramble for the machines.

Prices for such equipment, used to treat the sickest patients, have rocketed, with the market price for one particular model increasing from £21,700 to £77,100 in a single week.

What is a ventilator?

A ventilator is a machine that helps a person breathe by getting oxygen into the lungs and removing carbon dioxide

Ventilators can be used to help a person breathe if they have lung disease or another condition that makes breathing difficult. They can also be used during and post-surgery

A tube, connected to a ventilator machine, is placed in a person's mouth, nose or through a small cut in the throat (called a tracheostomy)

The project started when Dr Jakob Mathiszig-Lee contacted engineers at the university after "hearing the horror stories" about ventilators being in short supply in Italy from colleagues at the Royal Brompton Hospital.

Dr Joseph Sherwood, the project's leader, created the first prototype in three days but avoided using many of the "specialist components" used in other more expensive models.

The research fellow in the university's department of bioengineering said he previously had "no knowledge of ventilators at all".

"I think that was the secret to our success in a way because I didn't try and rebuild existing ventilators, I didn't know how they worked," he said.

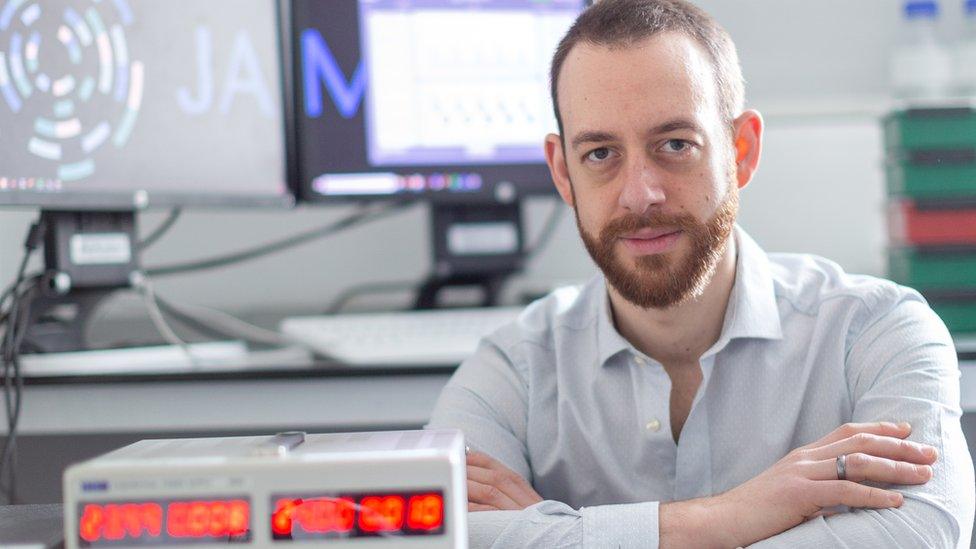

Dr Joseph Sherwood said he had no knowledge of ventilators before the government appealed for more to be made

The JamVent team said they had been in contact with the UK government, but now many companies, including Dyson, have been told their services are no longer required.

The team hopes the testing processes could be completed as soon as possible, but under normal circumstances it takes typically a year for the Medicines and Healthcare Products Regulatory Agency to sign-off a product.

Due to the low cost of device, the team believes that if it passes clinical trials, it could be used in the developing world, and "not just for this crisis".

"We have made this design for the benefit of the world and we have shared the design so people can take it up," said Dr Sherwood.

The project team has held discussions with manufacturers and investors, but is seeking financial backing from governments.

They estimate £5m would see the product made and distributed through "several manufacturers" in an "appropriate regulatory-compliant manner".

The JamVent ventilator uses parts which are much cheaper than other ventilators on the market

- Published24 April 2020

- Published16 April 2020

- Published24 March 2020

- Published17 March 2020