Tata steel: What do plans mean for UK's carbon footprint

- Published

Tata says the switch could slash the site's emissions by around 85% a year

Climate change targets as well as cost pressures are behind a major overhaul of the UK's largest steelworks.

Tata's Port Talbot plant is also the UK's biggest single emitter of planet-warming carbon dioxide.

The company's plans to shut its blast furnaces could cut Wales' carbon emissions by as much as a fifth.

But critics say the local community's paying an unfair price with thousands of jobs lost.

One think tank said it showed the UK and Welsh governments were failing to deliver a "just transition" to a greener future.

What's the issue with blast furnaces?

Making steel from scratch in a blast furnace creates a lot of emissions.

Carbon in the form of coal is a key component in the actual chemical process.

It's needed to remove oxygen from iron ore, leaving pure iron to be turned into steel.

But the oxygen and carbon combine to form, you guessed it... carbon dioxide.

The site's constant need for masses of power to run its operations 24 hours a day also adds to its carbon footprint.

Wales and the UK are among many countries to have set legally binding net zero targets to stop adding more carbon dioxide to the atmosphere by 2050.

An electric arc furnace at a steel plant in Izhevsk, Russia

What is an electric arc furnace?

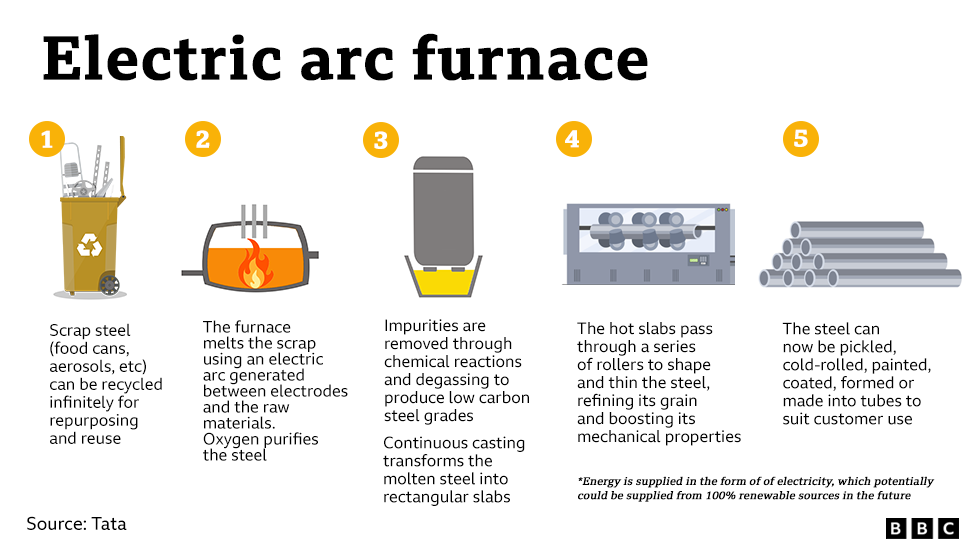

Switching to an electric arc furnace at Port Talbot would take the steelworks in a different direction.

Rather than making new steel - using raw materials dug from the ground - it would mainly be melting down scrap metal.

As the name suggests - the new furnace would run off electricity - the idea being that over time more and more of this would come from green sources like wind and solar.

"A lot of recycled steel is gathered together and three large graphite electrodes are lowered into it," explained Dr Becky Waldram, of Swansea University's Sustain research centre for decarbonising the steel industry.

"An electric arc is generated between those electrodes and it can reach temperatures of around 3,000 degrees which then melts the scrap down to be turned into other products."

Steel is the most widely recycled material in the world - and the UK produces 10m tonnes of scrap a year, much of which is currently exported to steel plants overseas.

What does that mean for the site's emissions?

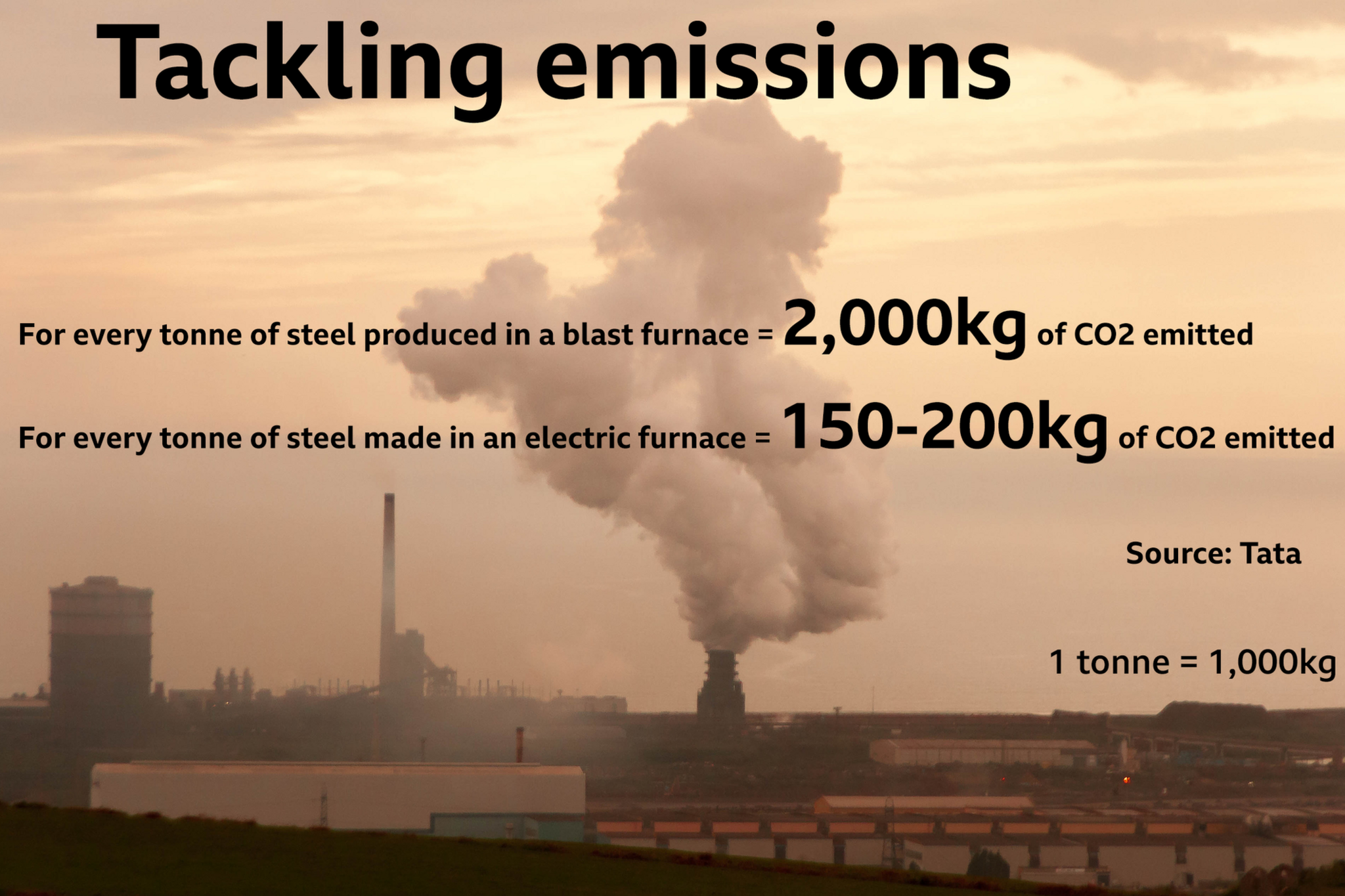

Tata says the switch could slash the site's emissions by around 85% a year.

It's a cut that equates to the annual emissions of almost 2m homes.

For every tonne of steel produced via the blast furnace method, they currently emit around two tonnes of carbon dioxide. This would reduce to between 150kg and 200kg from an electric furnace.

While some coal will still be required, they aim to reach net zero by 2045 by exploring options like carbon capture technology and green hydrogen fuel in future.

In the meantime, the impact for Wales' overall emissions is striking - somewhere between a 15 to 20% cut, while the UK's emissions could fall by approximately 1.5%.

But when official UK emissions stats are worked out they don't take into account the carbon impact of goods we import from overseas.

And steel unions say what's happening at Port Talbot will leave the UK reliant on buying in steel from countries which aren't moving as quickly to greener production methods - at least in the short term.

It will be four or five years before the new electric arc furnace is built.

You've then also got the carbon dioxide emissions associated with transporting that steel by ship to the UK.

Life is never ideal and we have to do it as manageably as we can with as little impact for families on the ground

What are environmentalists saying?

Kathy Oakwood, coordinator of Friends of the Earth in Neath Port Talbot said she wanted to see greener steelmaking for the planet's sake.

But she argued planning for the change had been left "to the eleventh hour", meaning "a balancing act" was now needed to protect jobs in the community.

She, like the steel unions, favours keeping a blast furnace going whilst the new electric one is built.

"We're in a transition," she says.

"Life is never ideal and we have to do it as manageably as we can with as little impact for families on the ground."

The Institute of Welsh Affairs said both the Welsh and UK governments should have done more to help prepare workers and ensure there were green jobs to go to in the area.

"The transition to net zero is going to start feeling like a cost and a burden and something that's putting their jobs at risk - rather than a positive vision of a green future," warned policy and external affairs manager Joe Rossiter.

Economy Minister Vaughan Gething has said the Welsh government places "huge importance and emphasis on a just transition in our move to a net zero economy".

He has said the economy would change, but if this was planned well, we could take advantage of new opportunities and minimise compulsory job losses.

Both Welsh and UK governments have said they are part of a £100m transition board plan to help affected workers re-train and find new jobs.

Welsh Secretary David TC Davies said: "If 3,000 people are going to lose their jobs, the UK government is not going to walk away, and not turn their backs on those people or that community."

STEELTOWN MURDERS: Three murders - unsolved but never forgotten

UNMISSABLE DRAMA: When the Wolf is at the door, be very afraid

- Published3 November 2023

- Published18 January 2024

- Published18 January 2024

- Published1 November 2023

- Published17 January 2024