Bloodhound diary: Supercar needs supertrack

- Published

A British team is developing a car that will capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the Bloodhound SSC (SuperSonic Car), external vehicle will mount an assault on the land speed record. Wing Commander Green is writing a diary for the BBC News website about his experiences working on the Bloodhound project and the team's efforts to inspire national interest in science and engineering.

I've just had a very odd experience - someone's sent me a video of myself appearing on Foreign Secretary William Hague's Facebook page. To try and explain this rather strange event, I'll start with my recent visit to the Bloodhound track in the Northern Cape of South Africa.

The Hakskeen Pan Track: A huge effort

I've just been to inspect the work on Hakskeen Pan, external, in the Northern Cape, where we'll be running Bloodhound SSC next year, as we test and develop the car up to our astonishing target of 1,000mph. The scale of the work required to prepare this surface is truly vast.

The car will need to do a number of test runs, so our main track is 500m wide, to give us multiple lanes to run on (each time the car runs on the hard soil surface, its metal wheel cut ruts, so each lane is one-use only).

The track is 12 miles (19km) long - which is just long enough to accelerate to 1,000 mph, then stop again before the desert ends. This process will only take two minutes, from setting off to coming to a halt 12 miles away.

In addition to the main track of 500m, we need a 300m "safety zone" either side of the track, in case the car gets very slightly offline - because "slightly" off at 1,000mph can mean being a couple of hundred metres sideways in the time it takes to correct the steering (for the sort of things that I might need to correct while I'm driving at 1,000 mph, have a look at "How hard can it be to keep it in a straight line?, external").

The team preparing the track has to remove a huge quantity of stones from the surface - an estimated 6,000 tonnes.

6,000 tonnes of stones, by hand

There is no mechanical way of clearing these without damaging the surface, so it all needs to be done by hand - all 21,000,000 sq m of it!

That's the equivalent of clearing a two-lane road, by hand, stretching from London to Moscow.

This is a task of biblical proportions and would defeat us without a huge amount of help - which is exactly what we are getting from the Northern Cape Government in South Africa.

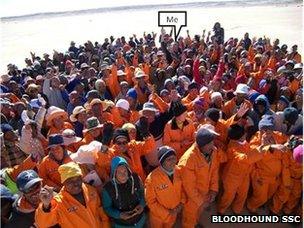

The Northern Cape is preparing the track for us, paying a team of 300 local unemployed people (moving 6,000 tonnes of stones - that's 20 tonnes each).

This will leave them as the owners of the World's Best Race Track and is, in the meantime, bringing some much-needed employment to the area.

This team has just finished clearing the 19km x 500m main track, so I went to see how it was looking, and to spend a bit of time working with the team and thanking them for their work (you can see some more detail on how it's looking in our latest desert update, external).

A team of 300 – and me

While I was working on the desert (and finding out just how hard and tiring the work really is), I took a small break to record a short video about the preparation work, external. The UK High Commission in South Africa asked for a copy - and that's how I finished up on the Foreign Secretary's Facebook page.

Bloodhound's long-term legacy is to excite a generation of young people, through our Education Programme, external, about the magic of science and technology (and if your local school hasn't already signed up to this free programme, get them to do it now!).

In generating this global Engineering Adventure,, external of course, we'll also be promoting British engineering on a global stage. This is exactly the sort of thing that the government's "GREAT" campaign is trying to achieve.

I'm proud that we will be helping to promote Great (make that GREAT) British engineering - and I'm equally proud of the stunning work that the Northern Cape is doing, as they build the world's best race track. I'm still surprised to be on William Hague's Facebook though.

The engineering part of our adventure is also coming along well, and our rocket test programme, external is about to move into the next stage.

Unfortunately, I can't give you any details (it would spoil the surprise), but watch this space - we've got a cracking event planned in the not-too-distant future.

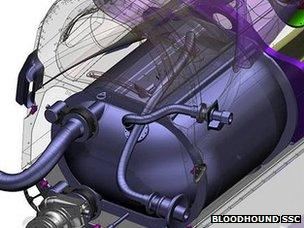

The HTP tank in Bloodhound

Meanwhile, the tank that will contain the rocket oxidiser (high test peroxide, or HTP for short) inside Bloodhound SSC is completing its design in preparation for manufacture.

The tank will be manufactured by ABC Stainless from thin-walled stainless steel (about 2-3mm thick) and will weigh around 80kg. It's going to have to carry 950 litres of HTP, weighing 1,320 kg. HTP is almost pure hydrogen peroxide (H2O2), hence it's nearly 40% heavier than water (H2O).

The tank (and the rest of the car) will have to withstand 2g of acceleration and 3g of deceleration, with an absolute limit of 9g (just in case).

During rocket firing, the tank will feed our pump motor (the 800 hp Cosworth F1 engine, external) with 950kg of HTP, which will all be pumped into the rocket (at 76 Bar/1100 psi) in 20 seconds.

If those numbers don't paint a picture for you, then imagine filling your bath in three seconds - that's the flow rate we're talking about.

The tank will be pressurised to 1.5 Bar (24 psi) during this process, to help supply this huge flow of HTP.

Liquid wheels

To make sure that there are no leaks or weak points, the tank will be pressure tested to 1.5 times this working load, and designed to survive 2.5 times the pressure if required.

There is no precedent for testing a hybrid-rocket-powered 1,000 mph car, so we've borrowed the test figures from another cutting-edge technology company - these pressures are based on Nasa protocols.

Good news on the wheels as well. The design for our runway wheels (which we will need first, for the UK runway tests next year) has been released to Castle Engineering. The tyres for the runway tests were originally designed for the Lightning jet fighter, but they happen to have the tall thin shape that we need.

We bought some unused tyres from the world's last Lightning operator - Thunder City in South Africa. So we've shipped UK-made tyres back from South Africa in order to test Bloodhound in the UK next year, before shipping it (still on these tyres) out to South Africa. It's a funny world sometimes.

The manufacturing process for the high-speed desert wheels has also been agreed with all the companies involved. The whole wheel manufacturing process will involve some four tonnes of aluminium, which Trimet is supplying in liquid form (did you know that aluminium is shipped as a liquid? No, me neither).

Otto Fuchs will then turn this large aluminium puddle into solid lumps (there are some technical terms involved like "casting" and "forging", but you get the general idea) from which we can machine the wheels.

The lower cockpit mould is born

The carbon fibre monocoque work also continues, with the production of one of the cockpit moulds, which is now ready for work to begin on the cockpit lower section. It's been a long time coming - can't wait to see my "1,000mph office" finally taking shape.

If you want to see how the whole process works, have a look at the latest Cisco BHTV video , external.

With the huge success of the Olympics only just behind us, we're looking forward to creating another global British success in 2013/2014.

The Olympics aimed to inspire a generation about sport, and of course to promote the team work and dedication that makes a successful athlete.

Look behind the science and technology of Bloodhound, and we are promoting exactly the same things - our engineers, and the hundreds of supporting companies, are the best in the world because they work hard at it, and they are building the world's first 1,000mph car together as a world-class team. The Olympics has done its bit, so now it's our turn - and I can't think of a better time to do it.

- Published27 July 2012

- Published26 June 2012

- Published24 May 2012

- Published23 April 2012

- Published19 March 2012

- Published24 February 2012

- Published20 January 2012

- Published19 December 2011

- Published11 November 2011

- Published10 September 2011

- Published18 May 2011

- Published26 April 2011

- Published5 March 2011

- Published7 February 2011

- Published21 November 2010

- Published13 November 2010