Bloodhound Diary: November date for debut

- Published

A British team is developing a car that will be capable of reaching 1,000mph (1,610km/h). Powered by a rocket bolted to a Eurofighter-Typhoon jet engine, the vehicle will mount an assault on the world land speed record. Bloodhound, external will be run on Hakskeen Pan in Northern Cape, South Africa, in 2016.

Wing Commander Andy Green, the current world land-speed record holder, is writing a diary for BBC News about his experiences working on the Bloodhound project and the team's efforts to inspire national interest in science and engineering.

Bloodhound's world debut date has just been announced, external: we're going to show the car off with a 200-plus mph run on 17 November this year.

While we regard 200mph as "slow-speed testing", it's still going to be quite a show.

We're aiming to get full reheat engaged on our ex-Eurofighter Typhoon jet engine, but I'll have to be quick on the throttle.

South Africa 2016

About two seconds after reheat lights up, we'll be doing 200mph and accelerating at close to 2g.

2g is the equivalent of 0-60mph in one-point-five seconds.

I don't care what car you have in the garage - this is faster.

Want to come and watch us run? Get your booking through the 1K Club, external today.

There's a slight disadvantage of finishing our test running in November, as we're going to miss the ideal weather window in South Africa.

Rather than press out to our Hakskeen Pan track in the heat of the summer and in the middle of the rainy season, we're taking the locals' advice and waiting until conditions improve.

We'll be doing our first batch of high-speed testing - and aiming to set a new supersonic FIA World Land Speed Record, external - in summer of 2016. Can't wait.

As we get closer to running Bloodhound SSC, we're testing more and more of the hardware. June was one of the more fun experiments, using a Jaguar F-Type to check Bloodhound's high-speed chutes.

F-Type Chute Testing

Our prototype chute can, designed to nestle next to Bloodhound SSC's jet engine, was mounted sticking out of the rear windscreen of the Jaguar.

While the F-Type can't get to supersonic speeds, its 180-plus mph runs were more than enough for us to test Bloodhound's unique chute system. In fact, it's more difficult to deploy a chute at slower speeds, as there is less airflow to pull the chute out.

Even at these (relatively) low speeds, the chute came out with a fair bang, as you can see from the video of the test session, external.

We happened to be testing the chutes in the same week that Nasa conducted a high-speed test of its new Mars lander chute (which sadly failed to deploy).

I'm delighted that our chute support crew managed a 100% success rate during our many test runs. Confidence in our team just keeps increasing.

The back end is growing

The car build continues steadily, if not quite as fast as seen in our latest build video, the 'hyperlapse' (yes, that's a real word, it just sounds made up) of "Building Bloodhound in 90 seconds".

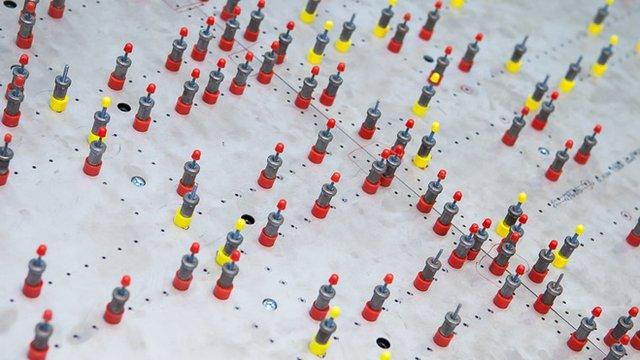

The RAF technicians are still busy this month on the rear deltas, which (to my untrained eye) look mostly finished now.

It's great to see the back of the car coming together, catching up with the front.

The car is looking more complete every day - it's exciting to watch.

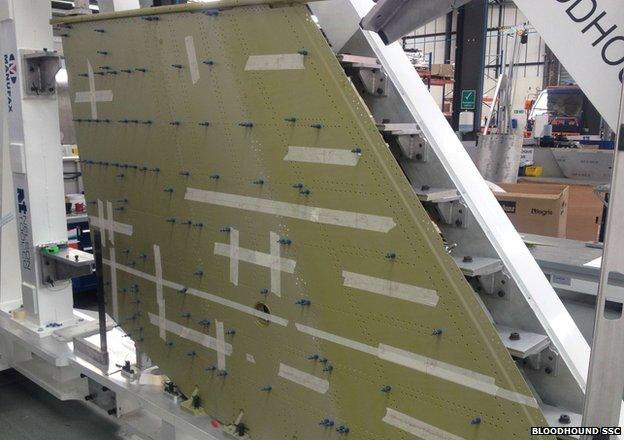

The RAF guys are also completing the final assembly of Bloodhound's fin.

This is one of the most important bits of the car, as it's critical to keeping the vehicle "pointy-end forwards" during each run.

Once it's finished, we've already got over 29,000 names to put on the fin, all wanting to go supersonic. Want to join them? Sign up here, external. We've got a special prize waiting for number 30,000.

Final assembly of the rear fin

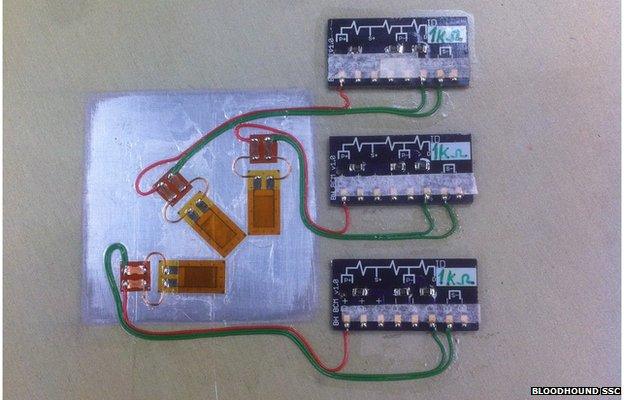

The fin loads are being very carefully measured, just like every other bit of Bloodhound SSC.

In this case, there is a cluster (known as a "rosette") of strain gauges on the inside of the skin, to measure the loads.

For Bloodhound's fin, three strain gauges are glued on to the skin in different directions.

A load on the fin will either stretch (or compress) the skin, at the same time stretching (or compressing) the tiny filament wires inside the strain gauge.

This will very slightly change the thickness of the wires, which in turn very slightly changes their electrical resistance.

Measuring this change in electrical resistance will tell us how much load the skin is suffering.

This will be monitored on every run. If the strain gauges see an unusually big load, then the computer will immediately illuminate a big shouty red "STRUCTURE" caption in the cockpit.

If this ever happens, it's time for me to stop the car so that we can find out what's going on.

Taking the strain

I'm not expecting this will ever happen, but it's nice to know the system is there to keep an eye on things.

The fin is stressed to 2.5 tonnes of working load, with a big safety factor on top.

For comparison, if we laid the car on its side, then the Fin could happily support 30 fully grown men standing on it, or 60 11-year olds. It's very strong.

Of course, it would normally be impossible to get 60 11-year olds standing still for long enough to test the fin like this, but don't underestimate the power of the Bloodhound Education Programme, external to enthral young people.

The programme continues to achieve amazing results, with some 100,000 students directly engaged over the past year, and many more following the project online.

World records and model rockets

As part of our Education Programme, we've launched a Model Rocket Challenge, external, to give students all over the world the chance to set their own Guinness world record. Last year, I spent a few days in Brazil, working with the British Embassy to tell Brazilian schools about the Bloodhound programme.

I've just heard that they are now planning to set up a Bloodhound schools rocket car competition across the whole of Brazil. I'm more convinced than ever that we're not going to be the first to set a new supersonic world record - a group of school children somewhere in the world is going to get there first!

Want to design a piece?

We've also launched another competition, to design the "keys" for the car, external.

One of our REME technicians is going to make the keys and the REME needs creative assistance - yours.

Race cars don't have normal keys to start them (possibly because they don't trust the driver not to lose them). Instead, we will have two electrical isolating keys on the outside of the car, so that the engineers can shut the car off from the outside if they need to. Time to get designing - good luck!

We've just finished the final design tweaks to the new "Bloodhound Driving Experience".

We tested it with a huge group of visitors to the Bloodhound Technical Centre and the feedback was terrific.

Comments ranged from "Is it really that difficult?" to "I want one of these at home!". Fancy a go? Come and try it at one of our public events this summer, external.

Our other June release has been the latest animation of the rocket system and airbrakes, external.

This video shows you what would be happening elsewhere in the car, while you're busy wrestling with the controls of the Bloodhound Driving Experience. Enjoy!

- Published12 June 2015

- Published10 June 2015

- Published3 June 2015

- Published19 May 2015

- Published7 May 2015

- Published28 April 2015

- Published2 April 2015

- Published25 March 2015

- Published14 March 2015

- Published6 March 2015

- Published2 March 2015

- Published3 February 2015